Optaglio, an anti-counterfeit research organization and the global leader in high-resolution security holograms, has introduced extremely resistant microholograms.

Documents, products, seals or other items can be equipped with a hologram to ensure anti-counterfeit protection because it can be neither copied nor imitated (provided that advanced technology has been used for hologram origination).

High-resolution e-beam lithography security holograms are considered the strongest anti-counterfeit measure available.

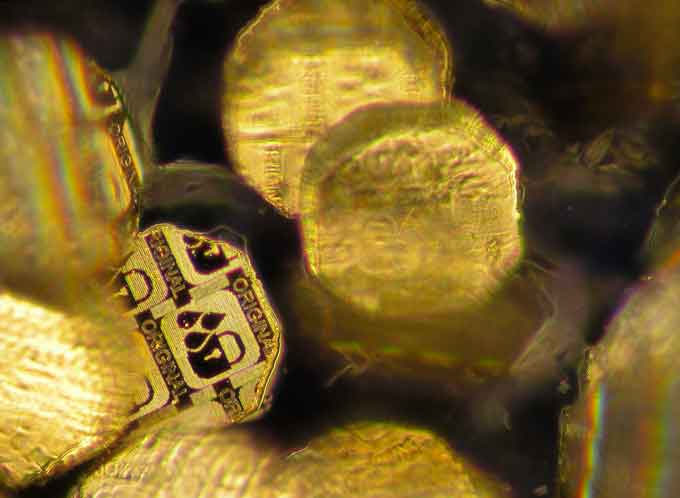

Microholograms are extremely small metallic particles (from 40 micrometers), which look like dots grains of metallic dust to a naked eye.

However, viewed under magnification, it is obvious that these particles are of regular shape and with holographic surface.

In addition to that, alphanumerical symbols can be engraved into the microholograms.

(Learn more. Courtesy of Optaglio and YouTube)

There are many ways microholograms can be applied to a protected item, including those that follow:

- µH Layer a µH Overlay products for polycarbonate cards

- Cover foil for other cards

- Hot stamping for paper-based documents

- Holographic paper containing microholograms

- Holographic lacker with microholograms

- Holographic stripes

- Holographic stickers

Microholograms are utilized to protect material (substrate) for a production of documents, stamps, products, etc. by blending tiny metallic particles of the size from 40 micrometers to half a millimeter into plastic, paper, foil, etc. which contains a complete hologram on each particle.

Microholograms appear as metallic dust to a naked eye.

However, an alarmed user can go deeper and inspect a document with a magnifier seeing their regular shape, engraved letters, and holographic surface.

If suspicion persists, it is possible to go even deeper and watch microholograms with a microscope, checking complete hologram with all visual effects and perhaps specific forensic features.

Optaglio’s new extremely resistant forensic measure for microholograms allows law enforcement experts to identify genuineness of documents destroyed by water, fire, acids etc.

While retaining all existing benefits of microholograms, such as covering three levels of inspection (visible, hidden, forensic) with a single tool.

New special microholograms are resistant against water, press, abrasion, mechanic stress generally, heat (up to 800°C), frost (up to – 80°C), radiation and some chemicals, such as xylene, petrol, acetone, toluene and a range of acids.

The lifetime of 10 years, keeping full resistance is guaranteed, but Optaglio researchers claim that real operating life will be much longer.

“The decision about genuineness now can be based on remains of completely destroyed documents,” says Tomas Karensky, senior research manager at Optaglio.

“At the same time, new opportunities open up in the marking of machine components and other items used in difficult conditions.”

“I would like to use this opportunity to express my appreciation to our colleagues from materials department. They did an outstanding job.”

Optaglio has manufactured microholograms since 2010 and has made significant innovations, over the years.

This technology is now accepted as a de facto industry standard for the multilevel protection of documents.

Microholograms enable several levels of inspection.

- Basic intuitive inspection by a naked eye (presence of microholograms),inspectors see metallic dust.

- Detailed inspection with a magnifier (letters engraved and presence of holographic surface)

- Forensic inspection (view through a microscope show holograms with all visual effects)

“Of course, the current state is not the end. We are working on further improvements,” added Karenský.

Resistant microholograms were developed in Optaglio Labs, where several research units work at the same time, including university cooperative projects.

A number of the projects are supported by European Union funds.

Optaglio is a research organization and the global leader in high-resolution e-beam lithography security holograms.

For nearly 25 years, Optaglio has delivered billions of holograms to governments, card manufacturers, security printing companies, premium brand producers and other organizations in more than 50 countries around the world.

Optaglio, is certified to relevant international standards, operates under strict 24/7 security supervision. Their comprehensive security system covers people, processes, data and facilities.

The company is a member of International Hologram Association (IHMA) through which it registers all its security devices and holograms in the central security register, in London.

To Learn More, visit www.optaglio.com.