By Scott Espensen, Perimeter Security Product Manager for Ross Technology

Retractable bollards serve as a practical solution for safely securing access points shared by both vehicles and pedestrians because they limit vehicle access when deployed, while still allowing pedestrians safe and unrestricted walking access.

As a result of this flexibility, they are an ideal solution for protecting entrances to public spaces with high traffic volumes such as outdoor shopping districts, museums, stadiums, parking garages, office buildings and more.

Given that these applications are most often found in metropolitan areas, however, the use of standard retractable bollards, which generally require 6 to 8 feet of excavation, is often restricted due to existing underground utilities and infrastructure.

Ross Technology’s XT-2200 Heald Raptor Bollard, the world’s only shallow mount retractable bollard, is the solution to the underground utility dilemma.

It’s engineered to require a mere 20-inch depth while meeting crash test certification to ASTM F2656 standards, with a M50-P1 rating.

The Risk of Installing Standard Bollards in Urban Areas

Major cities host a labyrinth of utilities, sometimes only a couple of feet underground.

Sewer, gas, water, cable and electrical lines pose potential planning headaches for architects, and offer worst-case-scenario outcomes if improperly accounted for.

Even with existing utility maps, and the aid of utility locators, it can be difficult to know with 100 percent certainty where all utility lines lie in a given metropolitan area.

The cost of repairing damaged utility lines or relocating these utilities to make way for bollards can grow into the tens of thousands of dollars.

In addition to utility lines, a number of other underground obstructions can limit excavation, including parking garages, subway systems and mechanical equipment.

In some areas, relocating utilities is not an option.

For example, in metropolitan New York City, there are areas where the density of existing utilities—both known and unknown—makes relocating utilities impossible.

In those instances, the chance of damaging a utility line is too great to take the risk of installing standard retractable bollards.

For scenarios like these, there is only one retractable bollard solution: the XT-2200 Heald Raptor Bollard.

Introducing the World’s Only Shallow Mount Retractable Bollard

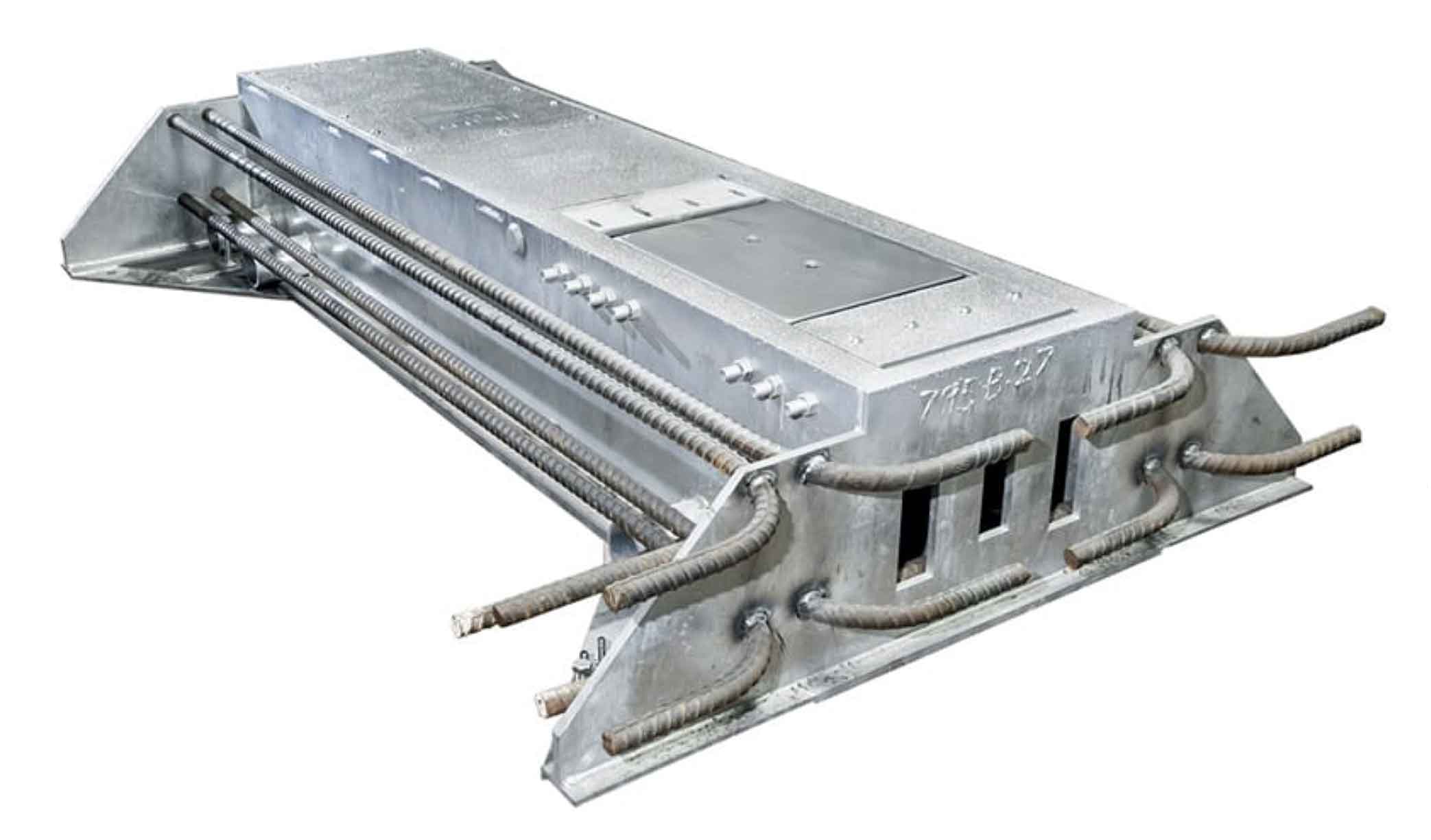

Manufactured in the USA by Ross Technology under license from Heald Ltd., the Raptor overcomes the installation limitations of standard bollards by requiring a mere 20 inches of excavation—compared to 72 to 96 inches for standard retractable bollards.

The XT-2200’s curved design the XT-2200 extends 39 inches above grade when deployed—yet its foundation, a compact 20″ d x 69″ w x 110″ l requires only 3 cubic yards of concrete.

This efficient installation footprint eliminates a great amount of risk to damaging utility lines that could cause electrocution, explosions or high-pressure releases.

And the benefits of the Raptor shallow mount bollard don’t end there.

How the XT-2200 Raptor Shallow Mount Bollard Saves Money

Installation cost

Compared to standard retractable bollards, installation for the shallow mount bollard is more cost-effective.

Excavation depths for standard bollard systems, as well as the amount of concrete needed, are triple what is required for the XT-2200.

These additional costs are seen not only in the amount of product (concrete, rebar) required, but in labor costs as well.

The Raptor requires no pre-casting of the foundation pit and includes integrated rebar, eliminating the need to supply and build rebar mats onsite.

Singular stopping power

Unlike many bollard systems, which are crash tested in an array of three units, the XT-2200 Shallow Mount Bollard was crash tested as a single unit.

Because of this, it can potentially be used to block a single lane more cost-effectively.

And since only one Raptor bollard was needed to achieve an ASTM F2656 M50-P1 rating, installing multiple units would sharply increase stopping power against a vehicle ramming attack, in contrast to standard bollards or even traditional shallow mount wedge barriers.

Cost-effective replacement of standard bollards

The Raptor can save money when it comes to replacing existing standard bollard systems.

Where an entire 6 to 8 feet of existing concrete and rebar must be excavated and removed to install a new standard retractable bollard system, a crew only needs to remove the top 20 inches of an existing foundation to properly prepare for the XT-2200.

The XT-2200 Raptor is Ideal for the Following Conditions:

-

Non-Standard Roadway Widths

- The Raptor can secure narrow roadways more cost effectively than typical three-bollard arrays and can also be installed as multiple units to provide heavy security for wide entrances.

-

Pedestrian and Bicycle Access

- Non-vehicular traffic can move through freely while the bollards are in the secure position

-

Safe Operation

- Unlike many wedge-style barriers, there are no hazardous pinch points and no need for a safety skirt

-

High-Speed Impacts

- Where the roadway layout allows vehicles to reach higher speeds

-

Minimal Setbacks

- Where critical assets or equipment are located close to entrances (such as in urban areas) and a high level of security is required regardless of potential vehicle speed

-

Fast Deployment

- Where the barrier needs to be deployed quickly because it is located close to a guard booth and reaction time is therefore minimal.

- The Raptor is raised and lowered with a double-acting hydraulic cylinder for long-term reliability.

- Normal operation cycle time is 5 seconds and Emergency Fast Operation (EFO) cycle time mode is 1.5 seconds.

-

Site Restrictions

- Where flush mounting with the roadway surface is required for snow plowing or where buttresses and posts used in other barrier designs would prevent access to wide vehicles

-

High Traffic

- Used as a final denial, this barrier can be used in tandem with standard traffic arms to quickly process a high number of vehicles

-

Architectural Appeal

- Contemporary style offers a modern twist on the typical bollard design

-

Flexible Controls

- Bollards can be controlled independently or in small groups to create more zones of control

Whether securing a tourist area, public facility or government building, the XT-2200 Heald Raptor Shallow Mount Bollard allows you to bring heavy-duty anti-ram protection to the most challenging installation sites.

About Scott Espensen

As Perimeter Security Product Manager, Scott Espensen oversees new product development, product testing, sales, project management and fulfillment.

With a strong background in controls technology for the United States Air Force, Scott has been very active in creating and sourcing advanced control systems for Ross Technology Perimeter Security products.

He has worked at Ross Technology for over 20 years, and during that time Scott has overseen numerous security projects in the Middle East.

Scott can be contacted at ScottE@RossTechnology.com.